Corporate profile

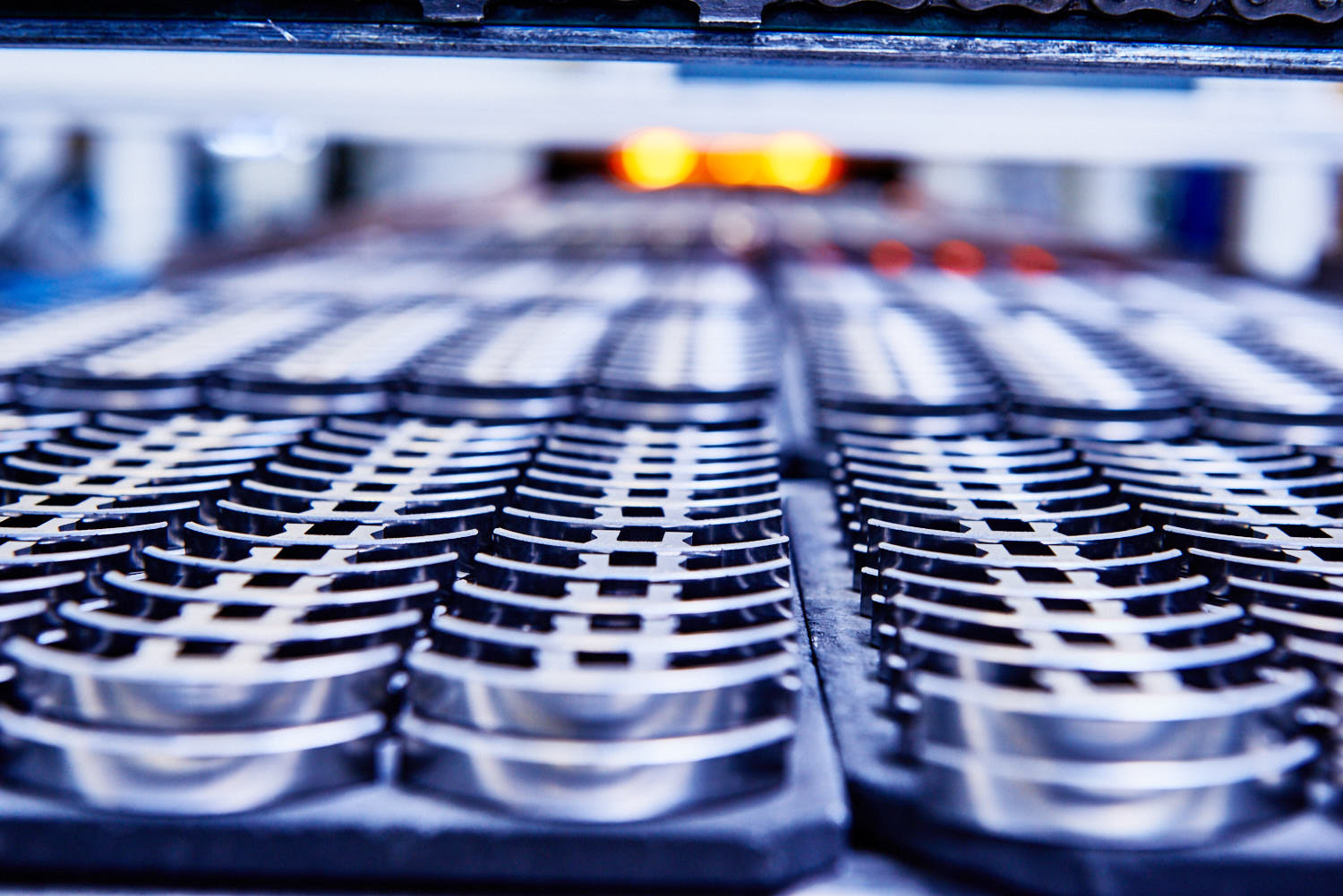

Toolmaking in a class of its own

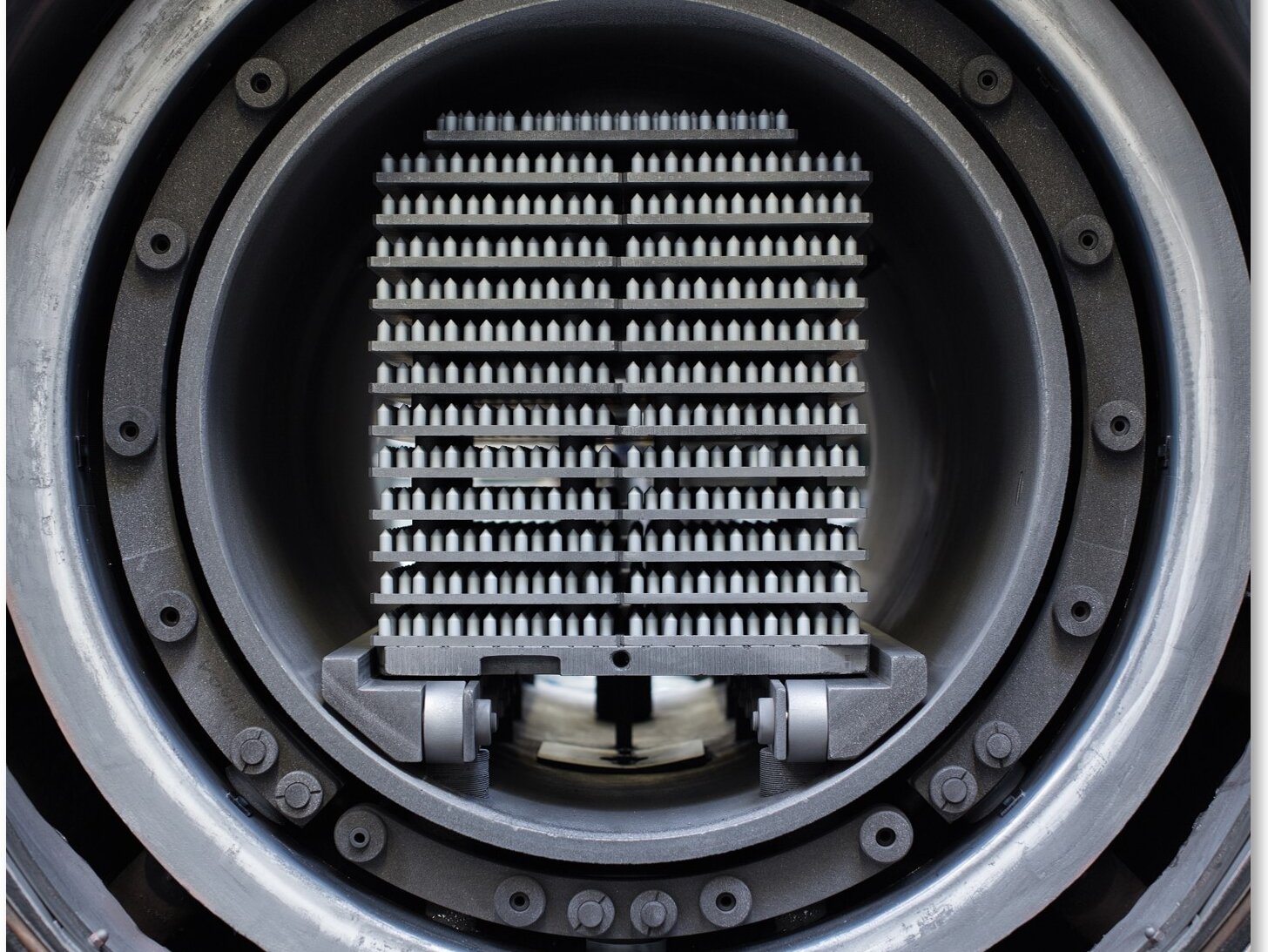

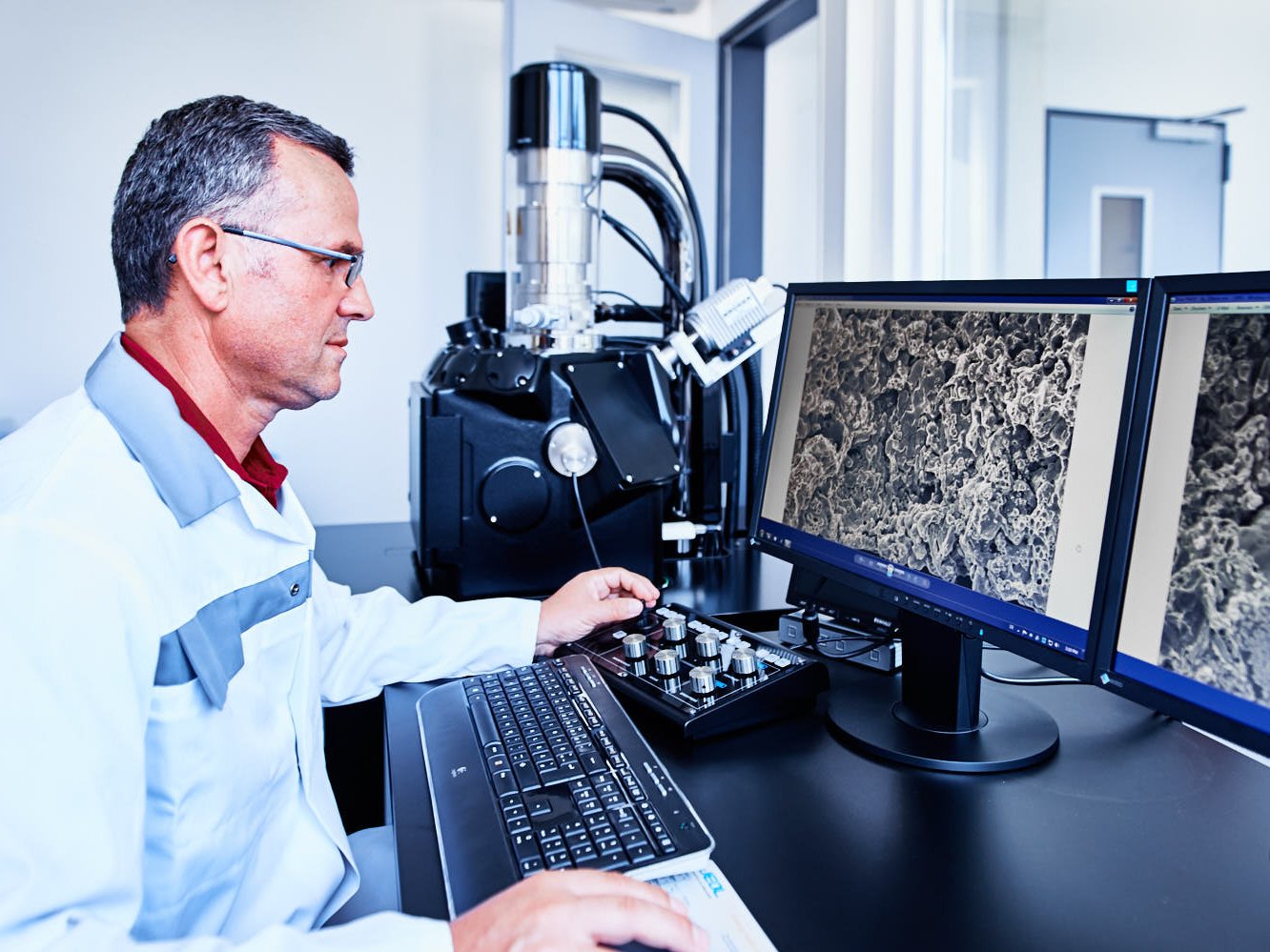

At SIMON Tooling, we manufacture high quality tools for our own needs of our business divisions BETEK, SITEK and SINTERLUTIONS. The special requirements of these areas with regard to quality and adherence to deadlines are a daily incentive for us to maintain our work at the highest level and to continuously improve it. All tools for the business divisions of the SIMON GROUP are developed, designed and manufactured centrally at SIMON Tooling.

In addition, we also offer our unique manufacturing expertise and our efficient service center to external customers and partners. In doing so, we maintain an open and cooperative relationship – always linked to the goal of developing the optimal solution for each of our customers. This applies to maintenance, as well as to the construction of samples or the production of small series.

Management

Our solutions set standards in user-friendliness and cost-effectiveness. Leading machine manufacturers worldwide appreciate this

Dipl.-Ing. Tobias Hilgert & Dr.-Ing. Marc Siemer